The American Mercedes Manufactured in Astoria Queens

Most car enthusiasts do not realize that an American Mercedes automobile was manufactured by the Daimler Manufacturing Company in Astoria, Queens from 1905 to 1907.

The complex story of the Amercian Mercedes was written by Michael Salemi and published in the current edition of The Star, the national magazine of the Mercedes-Benz Club of America. I am pleased that Michael Salemi and Gary Anderson, the editor of The Star, have provided VanderbiltCupRaces.com a pdf of the article "The American Mercedes: The nearly forgotten story of the Mercedes from Long Island". Please note the material is copyrighted by the Mercedes-Benz Club of America (www.mbca.org), and reprinted with their written permission.

Here are a few highlights and images from the article from The Star, which is usually available only to MBCA members:

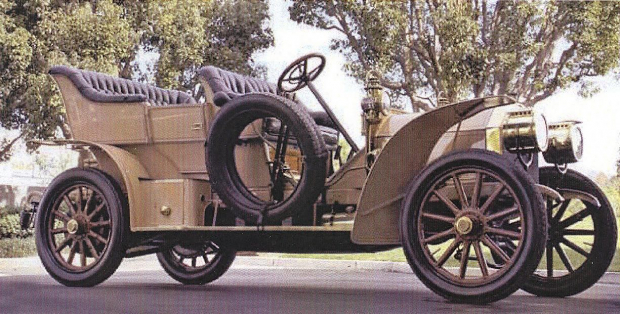

"The relationship of components to one another was established by this time, with the radiator in front of the forward-mounted engine, and the transmission behind it. The Mercedes was still chain-driven to the rear wheels, but this system would be replaced by a single driveshaft in 1908. The driver was mounted in front of the passengers with a steering wheel connected to the front wheels, with all controls within reach."

From 1905 to 1907 fewer than 100 American Mercedes were produced in Astoria, Queens. The cost of the car in 1905 was $7,500 equivalent to $175,000 today. All parts were interchangeable with the German Mercedes.

"The structure consisted of a body mounted on a lengthwise frame, a structure still used on many vehicles today. Leaf springs were installed between the frame and the wheels to cushion the ride, though shock absorbers were still very rudimentary, consisting of counter springs. The car even had a trunk, or basket, for cargo. The major differences between the American Mercedes and the German-built original reflected American road conditions, requiring a longer wheelbase and an additional two inches of clearance."

Thank you Michael and Gary for sharing this excellent article on a rarely known piece of Long Island automobile history.

Monday, January 17, 2011 Update: From Walter McCarthy: Here is that same American Mercedes pictured in the article on your site at a Long Island Old Car Club meet in 1947. At the time here in America it was owned by Mike Bonsera a club member. As can be seen in these two photos that wheels were cut down as they were on many cars back then as many tire sizes were unavailable. It is good to see that the museum in Germany finally gave the car a proper restoration as they had it for a number of years with the wheels still cut down.

_edited-1_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

Comments

I believe that the bodies were made by Steinway & Son’s pianos also located in Astoria next door to the Mercedes plant. IIRC, there was a personal connection between the Steinway’s and the Daimler family.

I worked in a building years ago and they told of the steinway pianos but also of turntables for vehicles that were in this plant in LIC they also mentioned coaches.quite possible same plant in article as spaces took up entire block .I will try to locate the address for you. Tom o. Enymga club

Hi Howard, I know the car and sent you 2 photos of the car when it was on L.I. It was owned by a local collector in New Hyde Park and later by a collector in Huntington. Regards, Walter

Hi Walter:

Thanks so much. I will repost on VanderbiltCupRaces.com this week.

Howard

Unfortunately the article in The Star is incomplete. To further complicate things, I will point to an article entitled “Keene may not race” from the Sept. 25, 1906 NY Times. It mentions the “Mercedes Import Company”, and identifies a Robert E. Fulton as the “Mercedes manager in this country”. If I am correct, Foxhall Keene’s Mercedes, which was the subject of the article, was purchased that day by George McKesson Brown. He employed my grandfather, William Luttgen to drive the #7 Mercedes in the 1906 race.

While not involved directly with DMFG to our knowledge, William Luttgen did share some history with them. As Howard has documented so well, William Luttgen had been a machinist, mechanic and driver for Daimler in Stuttgart. He was employed as a mechanic by Foxhall Keene in the first Paris to Madrid race, and the 1902 Gordon Bennett Cup Race in Ireland. Keene then helped Luttgen find employment at a machine shop in NYC when he immigrated in 1903.

Luttgen’s experience with Mercedes brought the company much business and he asked the three owners of the machine shop if they would consider taking him in as a partner if he could get a Mercedes agency for them. They agreed and in 1905 he traveled to Germany and secured importation rights to German made Mercedes. Soon afterwards Charles Loft, of the Loft Candy Company, loaned Luttgen the money to buy out his three partners.

Luttgen’s business was called “The Mercedes Repair Company.” At some point I believe he held the exclusive right to import Mercedes to all the Americas north of the Panama Canal, which he held until April of 1923.

To our knowledge, his only connection to the American made Mercedes has to do with Krupp nickel steel, and the Liberty aircraft engine of WWI. You see, in order to save import taxes on finished parts, DMFG had imported rough Krupp nickel steel forgings, castings and ingots from Germany, which they then machined. When the Long Island factory burned down, my grandfather learned that the Krupp nickel steel had been stored in the basement of the factory, which had in turn had been filled with water while fighting the fire. He therefore purchased all the Krupp nickel steel for salvage, gambling correctly that the steel had been protected by water.

The story then turns to WWI, when Ford and Packard had contracts to build the famous Liberty aircraft engine. I believe a man named Lawrence had actually designed the engine, and he in turned had hired Luttgen to build the experimental engines. Luttgen built a concrete test cell where the engines were run until they blew up, at which time the reason for the failure was analyzed. Unfortunately, when Ford and Packard tried to produce the final engine design they had a problem with parts failing, including the rocker arms if I am correct. They then turned to Luttgen to find out why his parts did not fail; the answer being that he used the Krupp nickel steel that he had salvaged from the American Mercedes plant.

Despite what The Star article said about the Carnegie Steel company’s products at that time, we believe the only alloyed steel available during WWI of that quality was German Krupp nickel steel. Thanks to the Long Island fire, Luttgen had the only supply of it in the United States. As a result, both Ford and Packard subcontracted with the Mercedes Repair Company to make those critical parts for the Liberty engines.

Robert Luttgen

A fascinating story of one man’s success story in the New World, and the links to the Steinway Co. and Daimler Benz adds more interesting detail. Thanks to the family for the great story.